RE-MED describes its technical visit of a demolition waste recycling plant in Italy

On 29 of March 2022, the partners of RE-MED project visited a construction and demolition waste plant in Trapani (Italy). The visit was conducted by Gizella Mammo Zagarella, the manager of the plant.

The technology used by Calcestruzzi Ericina Libera Soc. Coop. R.O.S.E. Plant (Recupero Omogeneizzato Scarti Edilizi) has low environmental impact, low energetic consumption, high level of selection of materials, high production flexibility and efficient recovery of metals.

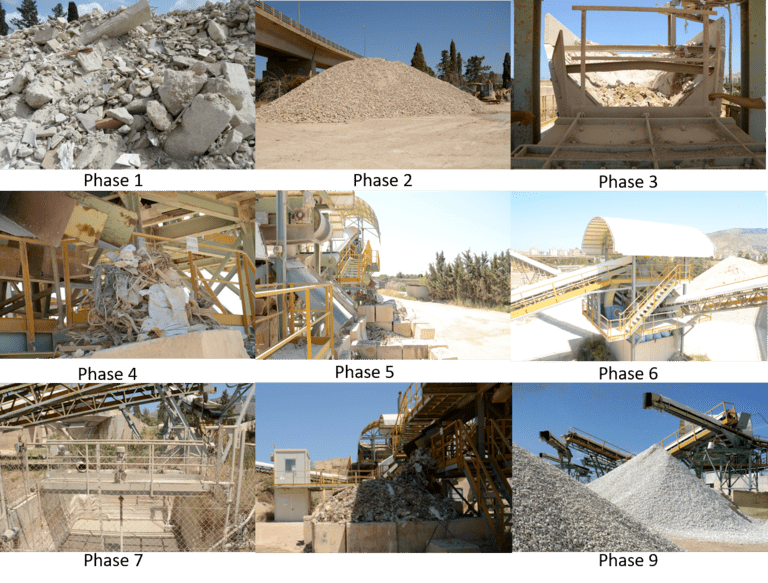

The process of transforming waste to recycled materials aible to be used as aggregate is composed by eight phases, described in the figure:

Phase 1 – Control & Inspection

The material arrives and is weighed, documents are checked and video cameras monitor the material and the plant.

Phase 2 – Weighing, Sizing & Sorting

Sand and fine products smaller than 8 mm are separated. This is the so called “granular pre-classification”.It is done to avoid energy wastage due to unnecessary milling

Phase 3 – Milling

The material is grounded to free metallic particles embedded in larger blocks and to prepare the material for reuse.

Aggregates and other Construction &Demolition waste (C&Dw) are up to dimensions of 100 mm

Phase 4 – Primary Removal of Ferrous Metals

The first phase to remove ferrous metals uses an electromagnet to separate inert matter from the metallic fraction. The metallic fraction is automatically separated for resale

Phase 5 – Secondary Removal of Ferrous Metals

A permanent magnet is used, placed far closer to the C&Dw. This allows the removal of more minute metallic particles.

Phase 6 – Vibrational Screening

In this phase a granulometric separation is conducted separating aggregates of various sizes:

- 0/28 mm

- 28/80 mm

- > 80 mm

Phase 7 – Flotation Separation

This phase separates the inert materials from one another, separating the light fraction i.e. paper, plastics, wood…, from the stone aggregates

Phase 8 – Ventilation

A second phase removes any materials belonging to the light fraction which have not already been removed.

Phase 9 – Homogenisation of the final product

Finally, only the stone aggregates remain and the now homogeneous aggregates are sorted by size and stored ready for resale.

Calcestruzzi Ericina Libera is capable of producing up to 100 tonnes of recycled aggregates each day

However, due to lack of demand for recycled aggregates, regulatory restrictions and costs associated with the production, the plant is very rarely operating at full capacity.